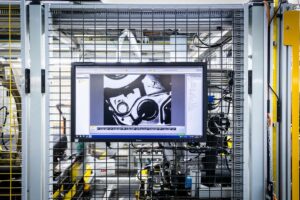

An example is the robotic workstation for tightening bolts on car seats for the Hyundai Tuscon.

A worker with a pneumatic screwdriver initially tightened the bolts on this assembly line. More precisely, it was three workers in three shifts.

The aim of the project was to automate this manual workstation while avoiding the situation where a seat leaves the station with an untightened screw, thus reducing the risk of human error..

Our robotic workstation design has been carefully considered with an emphasis on safety. We have used innovative muting barriers and a special entrance shape to match the seat. We also equipped the interior with a safety scanner to ensure the robot is not accidentally activated when a worker is confined in a cage.

The robotic workplace manages to tighten the bolts on one seat in 27 seconds with a production of 66 seats per hour with a success rate of 97%. The return on investment was set at about 1.5 years after costing.

Finding a suitable supplier was an important phase for Hyundai Transys. In particular, the requirements for safety, professionalism, and speed of installation were important criteria. After carefully selecting AUTOMA CZ was chosen and proved to be the ideal partner, fulfilling all the requirements at 100% level.