The automation of industrial production is one of the most significant trends today. We had the opportunity to discuss this topic with one of the most responsible. Mr. Slavoj Musílek is the managing director of the Czech company Automa CZ and a member of the Board of Directors of the Central European Automation Holding (CEAH) group, which brings together companies Automa CZ, Antra ID and Auware Engineering.

MM: How would you introduce Automa CZ and the CEAH Group CEAH?

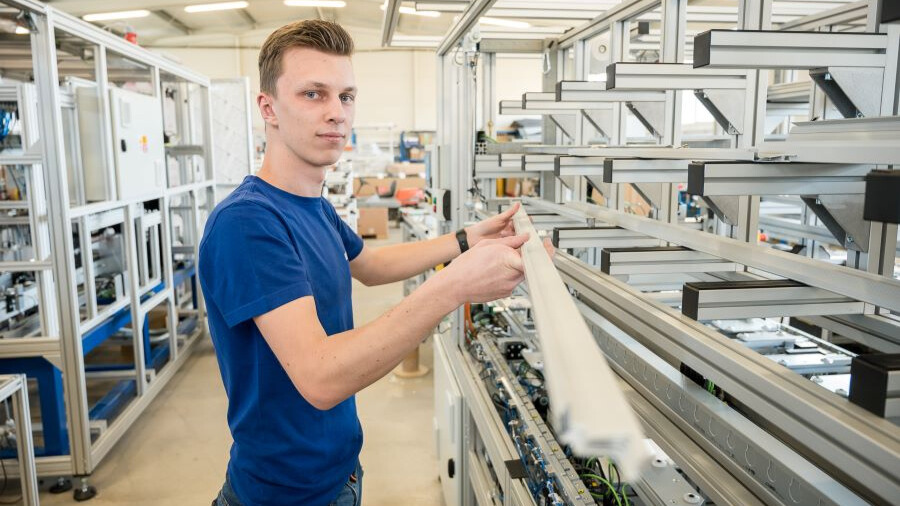

S. Musílek: Automa CZ is one of the Czech market's most important industrial automation suppliers. It primarily develops, designs, and implements single-purpose machines, assembly lines, and robotic stations. At the same time, we also offer top-quality related services such as service and training. Automa CZ was founded in 1991, so we will celebrate 32 years this year. In that time, it produced thousands of machines for international and local customers. And among other things, we can be proud that most of our customers have been working with us for several decades. This only proves that our services and solutions are truly of an exceptional standard. Automa CZ has been part of Central European Automation Holding since 2019. This project is a unique, interconnected group of companies from the field of industrial automation. Each of these companies is a market leader in its specialty. There is currently no company on the market that can offer solutions and services across the entire spectrum of industrial automation at such a level, with such experience and knowledge as the companies in our holding. Our goal is to be the strongest player in Central and Eastern European markets. We are building our holding from individual companies to become such a supplier and to be able to provide our customers with complete solutions and services for production automation and related intralogistics. Each company in the group primarily focuses on a particular area of automation. Automa CZ designs and manufactures machines, production and assembly lines, and robotic stations. At the same time, the Hungarian company Auware Engineering deals with value-added services, mainly programming of machines and lines and cyber security in production. Another Hungarian company, Antra ID Kft. focuses on solutions and services in the field of intralogistics automation. We want to expand the group so that we have cornerstones for each area of automation so that the individual companies can complement and help each other in their solutions, both in capacity and focus, experience, and know-how. Using them, we can expand our reach into other areas of the industry and win new customers.

MM: The Prague-based holding company currently brings together one Czech and two Hungarian companies. Does the international composition of the group bring you any problems?

S. Musílek: On the contrary, we consider the international structure a definite advantage, which is our goal. We want to be a strong regional player, so the fact that key teams of our companies are based in different countries is a unique advantage for us. We want to continue to expand in this way and include companies from Slovakia, Poland, and other countries, for example, in our holding.

MM: Can you briefly describe the course of a typical Automa CZ order and how it is implemented?

S. Musílek: First, we put our heads together with the customer, and together we clarify what the goal of the project is - what problem does the customer need to solve, what does he want to produce, and what are the specifics of the production process. After this is clarified, the discussion starts about what the solution should look like. The design of the solution (machines, stations, lines) in terms of concept and design emerges. Even at this stage, we work closely together, the customer comments on the proposed solutions, and we redesign and improve them. We start production when we reach a final design that the customer approves. We communicate with the customer during production and assembly. Acceptance tests are carried out; we take the machine to the customer and put it into operation. Then comes the follow-up services phase and the machine life cycle - for example, after a few years, the production program needs to be changed and the machine modified or a completely new one built. The partnership with the customer is usually long-term - we know each other very well and have built a relationship of mutual trust. We have been working with some customers in this way for 20 years or more. The projects of our other companies go through similar phases in principle, even though they may be solving problems in a different area of automation.

MM: What are the industries in which most of your customers operate? And are they more small and medium-sized or larger companies?

S. Musílek: Historically, the drivers of the automation industry have been large manufacturing companies, especially automotive companies and manufacturers supplying automotive parts. That is why these companies form our country's largest group of customers. In addition to the entire spectrum of suppliers for the automotive industry, our customers include electronics manufacturers and companies from the food and plastics industries. In terms of size, we have long worked with large multinational corporations such as Continental, Audi, Bosch, and Witte, but also with a long list of small and medium-sized local companies.

MM: Do you carry out projects more within the country or more often abroad?

S. Musílek: The primary market for Automa CZ is the Czech Republic; just like for our Hungarian companies, it is Hungary. However, we do not limit ourselves to local needs; our machines work all over Europe, from Ireland to Spain, France and Poland to Lithuania and Latvia, but also overseas, for example, in Mexico. For example, it is carrying out significant projects in Germany thanks to its expertise.

MM: Do you see any differences in the approach to automation between regions, industries, or companies of different sizes?

S. Musílek: We see great similarities between the market and companies in the Czech Republic and Slovakia, and these markets are very similar to those wests of our border. There is also a lot of investment in automation in Poland now, and in Hungary, the market is a bit more complex. And in Romania, for example, automation is booming. There are differences between countries, and they are mainly due to the different structures of the industry. In general, however, the waves of innovation in industry start in Germany and the UK and then spread from west to east across Europe. The current wave of automation is following this pattern. Today, we are in a situation where, even in Eastern Europe, small and medium-sized companies are beginning to invest massively in automation, robotics, and digitalization. This has been the case in the West for many years.

MM: I guess nobody approaches production automation to "get with the times." it must be worthwhile in some respect. What are the main motives that drive your customers to undertake automation projects?

S. Musílek: Companies invest in automation today because they have to. It's the only way to survive as a manufacturer in a competitive market. Automation helps them increase productivity and production efficiency, maintain consistent quality, cope with labor shortages, and ensure the necessary flexibility of production. Especially in pandemics, the ability to react quickly to sharp fluctuations in sales, material supply, and labor availability has proved influential. Changes to the production program are also becoming more frequent. Those who do not secure the necessary flexibility will end up in a competitive environment because they will be replaced by someone who can adapt better.

MM: What kind of return can companies expect when they invest in automation today?

S. Musílek: The payback time varies; of course, it depends on what you are producing and what automation issues you are addressing. In addition, an investment in automation is never a one-off. Instead, it is a never-ending process. An investment in a robotic station usually pays for itself in six months or a year, although sometimes it can take more than two years. Frequent changes in production schedules are also a reason to approach manufacturing technology design with maximum flexibility.

Whether and how production data is used, for process optimization and predictive maintenance that can increase productivity and efficiency also significantly impacts ROI. Digitizing production monitoring and data processing helps to minimize costly machine downtime, extend equipment life, etc. This results in additional savings that shorten the return on investment in automation.

MM: What do you consider your company's greatest asset, your advantage over your competitors?

S. Musílek. And customers will recognize that. Each of them will quickly discover whether or not the person they are dealing with understands the matter.

The second thing is access to customers. We always see the relationship with the customer as a partnership - always solving a common problem together.

Another key strength is that we always deliver what we promise. We always put the customer first; when we agree, we provide, even if it hurts. It is important for our partners that they can rely on us. Their success depends on being able to produce and return to their customers. We think of it as being in the same boat as our partners, and it's a long-term partnership.

I would also like to mention the advantage of direct customer communication with our developers and designers. The customer can contact someone who can help him very quickly with us. In addition, our partners appreciate that we solve problems right away. In addition, our companies are a bunch of people who know what they are doing and enjoy it. And that shows in the result of the work, and customers appreciate it.

Another significant advantage is the financial strength of the holding's owner, Oriens Investment Management. The solid financial background and cooperation of the companies in the holding allows us to implement even demanding projects, which one company alone would not be sufficient financially in terms of capacity or expertise.

MM: How many people work in your company? Do you have enough qualified employees? And how do you motivate them not to leave the company?

S. Musílek. The primary motivation for our colleagues is the varied and exciting work we enjoy. Every project is unique and takes us somewhere; our work is not a routine but an adventure, even though it sometimes requires a lot of overtime and extra work. Anyone who doesn't enjoy this and would rather spend eight hours daily doing the same job in a high-volume production environment probably won't be suited to our work style. It isn't easy to find quality people, and even vocational education, in my opinion, does not offer enough prepared graduates. We need to look for people willing to keep doing new things and learning and nurture those people. Once someone who fits into our company culture joins us, they usually stay with us. We work as a team; many of our employees have been with Autom for over 15 years, some even since the company was founded.