Automation has traditionally been associated mainly with large manufacturing companies, and the automotive and electronics industries have been considered its primary domain. Industry 4.0 has become very complex and challenging for the average person. Its name is often used, but few can explain the term's meaning. There is also the misconception about industrial automation, robotization, and digitalization that these are too complex and difficult to use in the everyday lives of small and medium-sized enterprises. However, this is a misunderstanding that needs to be corrected.

The growing need for automation applies to all businesses, regardless of sector, size, or location. Small companies, too, need smoother workflow management, better supply planning, more efficient logistics management, and the robotization of standardized processes. To increase their efficiency, flexibility, and productivity while maintaining high quality, they must also optimize maintenance costs, reduce spare part stores, and reduce the time between the initial ideas and product launch. They must also combat labor shortages and better use their workers' potential. To help SMEs cope with these challenges, industrial automation must disprove the myths hampering its deployment in this business segment.

Myths about Automation

Many very popular "myths of small and medium-sized enterprises" related to industrial automation exist. We can meet them here and in the neighboring countries of Central and Eastern Europe. To name a few: Our company is too small to automate. Our processes are so specific that they cannot be automated. Investing in automation will not bring additional economic benefits. Robotization is beyond our financial means. We do not see the need for automation because we have successfully lived without it. I cannot find enough qualified workers to take our production to the next level. Robotization takes people's jobs.

Let's look at the facts

One well-received indicator of automation is the so-called robot density, which is the number of industrial robot units used in the country per 10,000 employees. For example, this figure is found in the World Robotics Industrial Robots Report 2021, published by the International Federation of Robotics (IFR). This report provides 2020 density data for Europe: Germany 371, Sweden 289, Denmark 246, Italy 224, Netherlands 209, and Spain 203. Slovenia 183, Slovakia 175, Czech Republic 162, Hungary 120. These figures clearly show that the countries of Central and Eastern Europe are barely over half of Europe’s more "advanced" countries. On closer examination of the reasons, some are evident - more expensive vs. cheaper labor and companies’ economic power, to name a few. But the hidden driving force behind higher density is the adoption of automation across small and medium-sized enterprises (SMEs) and the wide variety of products in these countries - countries with higher productivity, efficiency, and better use of human-labor potential.

Isn’t that a good answer to the "we’re too small a business" argument? Why aren’t small companies in Sweden, Spain, or Germany "too small" to invest in intelligent automation solutions? The reason can be simple - they want to be competitive, efficient, and profitable and successfully support their goals by investing in automation.

Specific production

We can agree that some production processes are unique and challenging to automate. Still, many tasks, operations, and techniques have already been successfully automated, digitized, and robotized in hundreds of production facilities worldwide, bringing competitive advantages. There are many ways to be inspired. Talk to professionals in the automation field or spend some time on YouTube, where virtually everyone can find real examples of applications that meet their needs and solve their business or production challenges.

Work for employees

The myths relating to the workforce also deserve some clarification. Automation, digitalization, and robotization don't take people's jobs. Nowadays, employers need a more reasonable force, the scarcity of which is one of the constraints on the growth of their business and the achievement of new opportunities and markets. In such a situation, the solution is to free people from "PPAs" (dull, dirty, dangerous, tedious, dirty, and dangerous) activities and place them in positions that extensively use their human potential. This will enable them to develop their skills and provide more for society by increasing productivity, efficiency, and added value. Another challenge facing many firms today is the shortage of workers with the required skills. Since such people are unavailable and unlikely to be available soon, the way forward is to make better use of, develop and support workers already working for society. How? By automating, digitizing, or robotizing the PPAs.

Finance point of view

Many myths are related to the financial side of the story. Experience shows that the return on investment in intelligent automation is usually between three months and two years (depending on many factors), which are very acceptable values. Moreover, reasonable investments in automation, robotization, and digitalization seem to be necessary because they bring a significant competitive advantage, increase productivity and enable manufacturers to produce more with the same number of employees, switch from two-shift to three-shift operations without increasing the number of employees, improve quality assurance and reduce production shortages, shorten product launch times and increase flexibility to switch production to new opportunities and changing demand. So the investment here is not an investment in automation as such, but an investment in the success and future of the business because the business will lose its competitiveness sooner or later without automation.

Administration, production and logistics

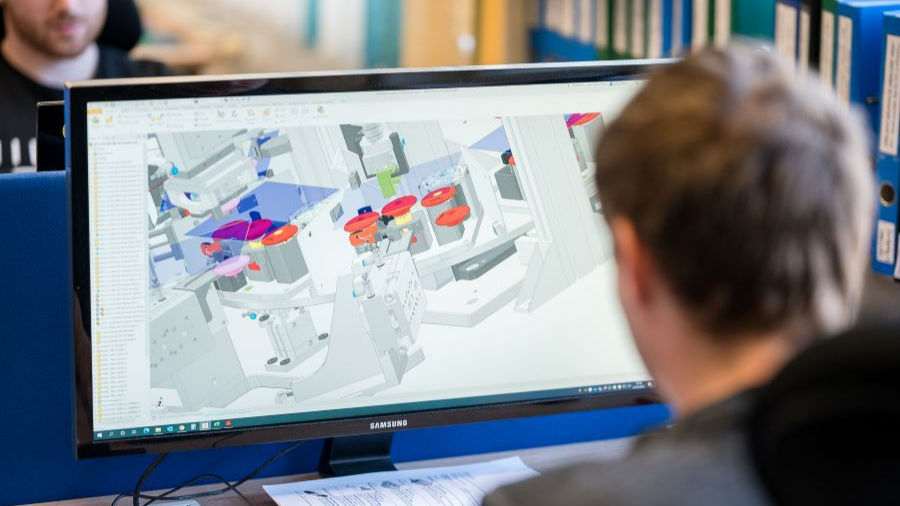

Automation and digitalization make it easier for manufacturing companies of all sizes to compare competing products, simplify purchasing, and form a completely different production and logistics operation. They leave their mark virtually everywhere, most visibly deploying automated and cyber systems in manufacturing processes. This means they replace routine manual procedures in production by introducing automated production or assembly lines. The main advantage is the saving of production costs; thus, reducing the unit price without reducing quality is possible. In contrast, automated and robotized lines significantly reduce scrap and allow more parts to be produced. Experience shows that the computer-controlled assembly line has up to a 97% success rate. This solution suits businesses of all sizes, as each key can be tailored to the customer's needs. One of the companies in CEAH, Automa CZ, is active in producing single-purpose machines, robotic stations, and assembly lines according to unique customer needs and requirements, which is not standard on the market.

Automation is also typical in which production can change to another product after a few months or years. This can be resolved well in advance by the intelligent design of the machine, station, or entire line, considering future production change needs to be effectively adapted to new requirements and redesigned, including customer reprogramming by our engineers from Auware Engineering.

Jednou z nejdůležitějších oblastí, kde se automatizace uplatní v každém výrobním podniku, je intralogistika. Takové řešení zahrnuje celkovou logistiku, řízení zásob a veškerou evidenci. V dnešním rychle se měnícím světě jsou digitalizované, bezpapírové, štíhlé procesy a sledovatelnost zboží a zařízení potřeba více než kdy jindy. Unikátní logistická řešení, využívající automatizované identifikační systémy (Auto-ID), pokrývají celý dodavatelský řetězec a umožňují plné sledování zboží, surovin, polotovarů a hotových výrobků.

Comprehensive solution from one supplier

There are many ways to automate manufacturing and intralogistics processes, and the subject may seem complicated at first glance. The advantage of Central European Automation Holding is that all of these solutions are under one roof. Thanks to the synergy of specially trained consultants, designers, programmers, and technicians from Automa CZ, Antra ID, and Auware Engineering, we can offer the customer the best services, solutions, implementation, and service in these areas. By fully exploiting synergies, competencies, experiences, and unique expertise within the group, our companies can meet our clients' demands in critical areas of automation, robotization, and digitalization today, from idea creation, design, and programming to programming commissioning and maintenance.